Acoustic Emission

Acoustic emission test is a new and advanced method in the field of non-destructive testing.

This method has been expanded in a wide range of non-destructive testing applications, such as inspection of Tank Storages, Piping systems, Reactors, etc., and this method can be used to detect and locate various defects in structures under load.

The Acoustic Emission Inspection is a passive technique that analyzes the ultrasonic pulses emitted by different sources inside the material at the moment of its occurrence, and this method is different with ultrasonic and x-ray methods.

While in these two methods to obtain information about the target part, it is necessary to apply external energy, in the acoustic method, the energy released from the target material is a reference for the inspection .

The rapid discharge of energy from a concentrated source inside the body causes the creation of transient elastic waves in the form of sound and their propagation in the material, which is called acoustic emission. These waves travel through the material and reach its surface.

The non-destructive test by acoustic emission method includes receiving these waves and analyzing them in order to establish a relationship between the received waves and the changes made on the source.

According to the propagation of waves from the source to the surface of the material, they can be recorded by sensors and in this way information can be obtained about the existence and location of the source of propagation of waves. These waves can have frequencies up to several megahertz. Ultrasonic sensors are used in the range of 20 kHz to 1 MHz to hear the sound of materials and the failure of structures, and the common frequencies in this method are in the range of 150 to 300 kHz.

The application of this method is not limited to the non-destructive inspection of various parts, equipment and systems, and it can also be used to estimate the life of parts and equipment. Also, this method can be used to detect and locate partial voltage discharges in large converters, research and investigate the properties and characteristics of materials, geology and micro-vibrations research.

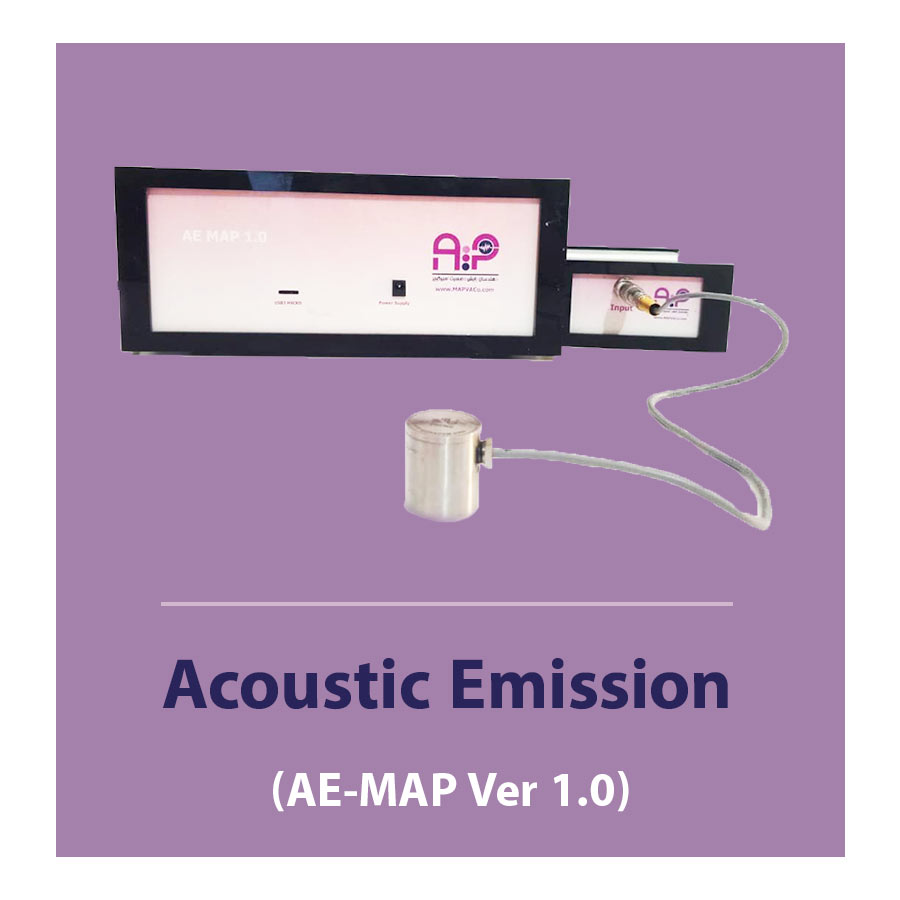

AE-MAP Ver 1.0

Technical Features

- Sampling Rate: 65 MHz

- Number of channels: 2, 4, 8, 16

- Connection: USB 3.0

- Resolution: 14 bit

- Adjustable Hardware Filters: 0 – 3 MHz (based on FPGA)

- High Pass Filter: 20kHz, 100kHz, 400kHz

- Low Pass Filter: 100kHz, 400kHz, 1200kHz

- Dynamic Range: 80 dB

- Operating Temperature: -10 – +60 degrees Celsius

- Input Impedance: 50 ohm

- Pre-amplifier: gain of 20, 40 and 60 dB

- Calibration: Based on BS EN 13477-2-2010 Part2

- Extraction of signal characteristics: energy, Kant, continuity time, peak-to-peak time, maximum amplitude, average frequency, maximum frequency, RMS.

Applications

- Leakage detection at the bottom of industrial tanks

- Piping Leakage detection

- Valves Leakage detection

- Locating electrical discharge in transformers for pressure vessel evaluation

- Online Monitoring of Production Process

- Safety monitoring of construction structures, bridges, etc.

- Monitoring rotating equipment, turbines, etc.

- Academic and university research activities in the field of non-destructive testing, such as investigating the failure of composites, drilling, etc.