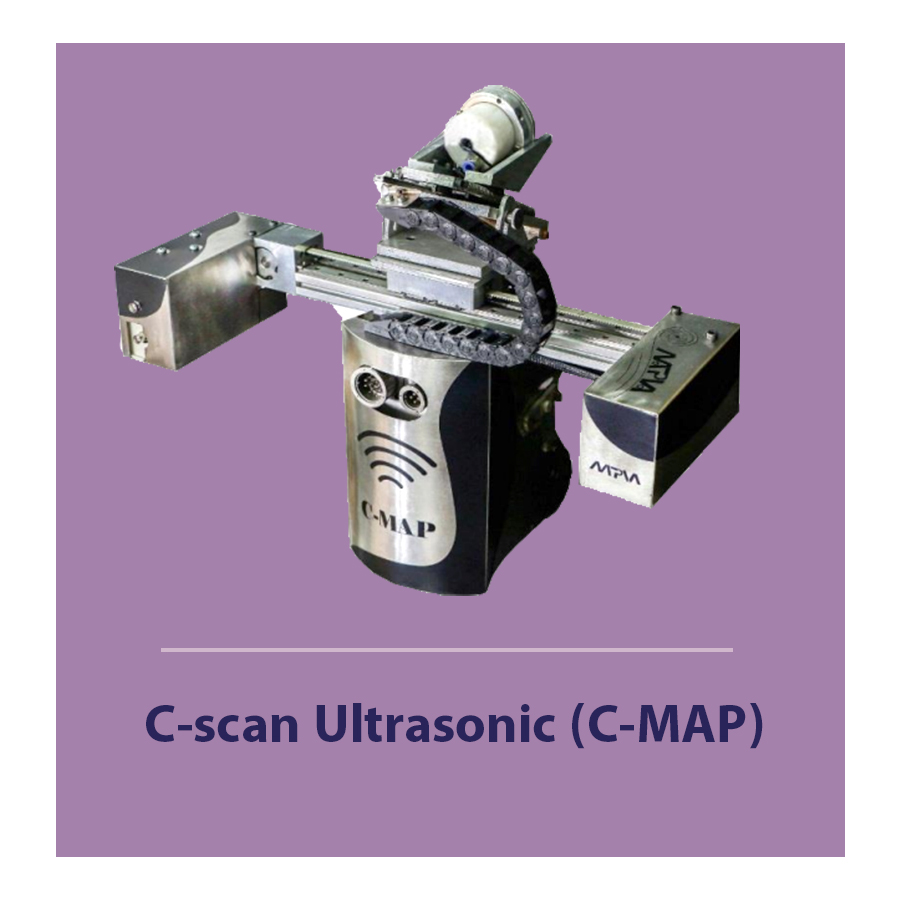

C-scan Ultrasonic

Ultrasonic scanning (C-scan Ultrasonic | C-scan) is one of the non-destructive inspection methods to control corrosion and identify defects in various industrial structures. In this method, the location and size of the defect can be identified by sending and receiving an ultrasonic wave inside the material and calculating the time of the wave’s round trip and the amplitude of the received wave.

The data collected from the ultrasonic device is shown as images with different color intensities. If there is corrosion or defect inside the structure of the work piece, this color change is noticeable and the location and extent of corrosion can be calculated.

The desired C-scan ultrasonic device has high speed and accuracy, and with remote control capability, it can be used to identify and evaluate corrosion conditions and defects in structures such as fuel and fluid storage tanks, pipelines, pressure tanks, and other important industrial equipment.

This capability increases the probability of POD detection and also enables engineers to determine the optimal strategy for risk-based inspection (RBI). The ultrasonic C-scan system consists of three basic parts.

- The mechanical part includes: device body, probe holder, linear and rotary movement system, magnetic wheels and power transmission system.

- The electronic part includes: servo motor and servo driver, probe linear movement speed controller and forward movement, data acquisition system, board and ultrasonic probe.

- The software and data analysis section includes: data processing software, signal analysis, 2D and 3D image drawing.

Device features

- High speed scanning (300mm/s) with real-time simultaneous image display

- High Probability Of Detection (POD) with 0.5mm step

- قدرت وضوح با گام 0.5mm×0.5mm

- Efficiency in high temperatures up to 150 degrees Celsius

- Inspection Capability up to a thickness of 150 mm or 6 inches

- Usable on metal materials from 150mm internal diameter to flat plates

- Scan width diameter up to 1m

- low maintenance costs

- No need to remove paint from the tank body during testing

- High quality of collected data

Inspection capabilities

- detection of cavities resulted from pitting corrosion

- Common corrosions

- Torque Laminations

- Internal coating defects

Software features

- Integrated scanning process control, data collection system, analysis and reporting tools

- A-Scan and B-Scan Real-time process Displaying during scanning operation

- Gates configuration for Defect detection and analysis

- Save and replay collected data

- Excel CSV Export

Driving and control system

This part includes the power supply system, the motion control system, the output of the motion encoder in the x and y directions and is controlled by a special software. This software is separate from the information collection software and the ultrasonic system

The drive system includes stepper motors, servo motors, magnetic wheels, and ball screw systems. The power transmission is applied by the stepper motor on the magnetic wheels and the forward system performs step-by-step movement. Also, the ultrasonic probe moves from the drive system through the reciprocating system, and data collection is done every scan.

Scanner efficiency table

Technical Data

Low noise preamplifier (0.74 nV/√(Hz))

High gain up to +92 dB

Switchable analog filters

Support fast TGC (time gain compensation)

2 signal inputs PE and T

T Input attenuator (-20dB)

Input Impedance 50 Ohm, 10pF

100MHz sampling frequency, 10bit resolution

Up to 512k x 16bit samples memory

Delay settings up to 65535 sample periods

Various triggering mode

BNC or Lemo analog connectors

Dimensions: L 100mm W 82mm H 32mm

DB15 connector: I/O lines 6 Inputs and 6 Outputs

USB 2.0 High Speed

Power supply: delivered by the USB connector (5 VDC)

Weight: 310g

Transducer

5 MHz 50 mm focus- Thickness range 6-12.5 mm

5 MHz 75 mm focus- Thickness range 12.5-50 mm

10 MHz 40 mm focus- Thickness range 1-6 mm

2.5 MHz 75 mm un-focused- Thickness range 50-150 mm

Input Amplifier

(Gain: 28dB to 68dB (step 0.5dB

Input Post-Amplifier: off or +24dB

Input Attenuator: off or -20dB

(Input Range: ±275mV (±2.5V with Attenuator active

(Full Bandwidth: 0.5 MHz – 25 MHz (-3dB

to see the other services and products click here.