Magnetic Flux Leakage (MFL) Inspection of Steel Wire Ropes

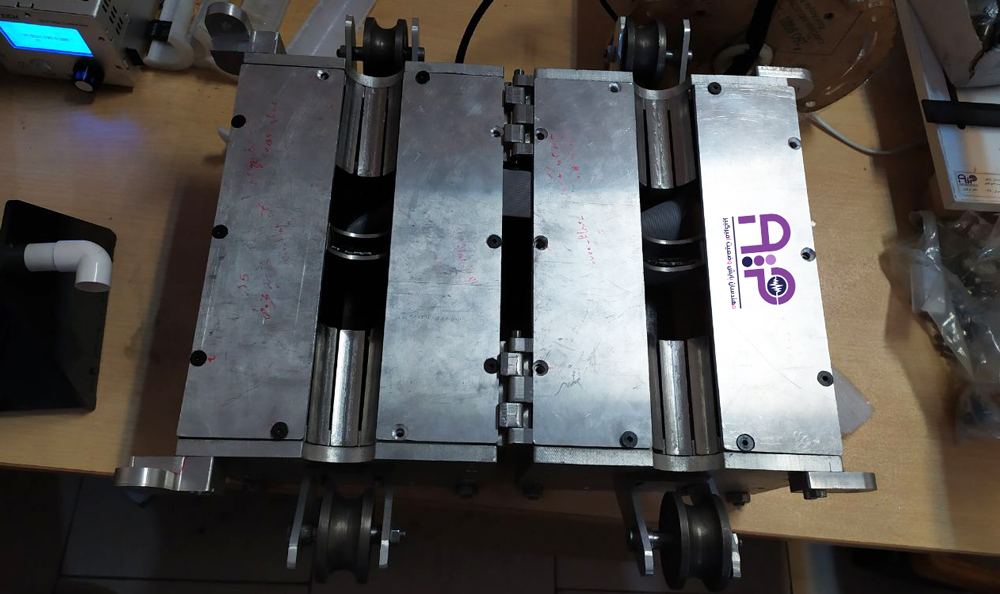

MAPVA Company Using its technical knowledge in the field of advanced non-destructive testing, has designed and Manufactured a steel wire ropes Inspection system using the Magnetic Flux Leakage (MFL) method.

The device has been introduced with the brand name (MAP-MFL). it is used to diagnose the defects of steel cables for the purpose of safety and reliability. This system evaluates and estimates the technical conditions and the reduction(defects) of the cross-sectional area of the cables as a percentage.

Generally, defects in the cables are localized (Local Flaw-LF) and changes are along the axis of the cables. As an example local defects are include; the breakage of steel wires in the cables due to excessive loading or fluctuating loads

Also, as a result of contact wear and corrosion in the cables, defects of reducing the cross-sectional area (Loss of Metallic Area-LMA) may also occur.

MFL-MAP system uses 20 differential magnetic sensors around the cable that prevents hiding defects (even very small) in the inspection.

This Device Can display the data changes online and also identifies the location of defects.

Due to the use of the magnetic method, the external coating such as plastic coating or covers on the cables (grease, etc.), does not disturb the troubleshooting process, and there is no need for cleaning and this is one of the advantages of this method.

General Features

This Device is made up of three separate parts:

- The Head is the first part of the device that cables passes through it and sensors and encoder are assembled in it.

- Data collection system including electronic board, anti-noise cables, wireless and batteries

- Software part is provided to show sensor data in the location of the defects

Technical Features

- Principle of Performance: Magnetic

- Diameter Measurement Capability: 6mm- 100mm

- Number of Sensors: 20

- Cable Movement Speed: 0.1m/s – 2 m/s

- Detect Accuracy: 1% reduction in cross-sectional area and a single wire cut

- Sampling Frequency: 2MHz

- Resolution: 8 bit

- Working Temperature: -20 to 60 degrees Celsius

- Battery Life-time: 20 hours of operation time

- Power Supply: battery or AC

- Calibration: Annually (based on relevant standards)

- Sensitivity: 13 mv/G

- Consumption: 50 mW

- Identifiable Defect Type: cross-sectional area reduction defect and local defect

- Classify Defects Ability: in 4 levels

- Required Standards: ASTM E1571, EN 12927-8

- Software: (MFL Soft) software with the ability to display sensor data changes and the location of defects Online

- Connection : Wireless

- Store Data: Up to 1 TB

- Cable Maximum Length: up to 30 meters

- Defect Classification: Statistical reporting of the types of identified defects and their classification

Order

Types of Heads for different cable diameters

| row | Code | Cable Diameter Measurement Range (mm) |

| 1 | MFL-MAP-H 10 | 6-12 |

| 2 | MFL-MAP-H 20 | 12-20 |

| 3 | MFL-MAP-H 30 | 14-32 |

| 4 | MFL-MAP-H 40 | 20-42 |

| 5 | MFL-MAP-H 50 | 30-50 |

| 6 | MFL-MAP-H 60 | 42-64 |

| 7 | MFL-MAP-H 70 | 60-80 |

| 8 | MFL-MAP-H 80 | 80-102 |

Crawler

For some situations the height of the end of the cable may be too long, so for easy Usage, the wireless system is used to move this device instead of cabling.

all the information is stored on the memory card, and after the inspection, all the information is placed in the computer and subjected for evaluation.

Crawler’s Features:

- Battery Life-time: 5 hours

- Weight: 25 kg

- Movement speed: 50 mm/s

- Withstand weight or load: 100 kg

- Motion Control System: Wireless